Ultrafiltration Plant: Working Principle and Application

Ultrafiltration Plant is working on a separation process that utilizes membranes with pore sizes ranging from.01 to.001 microns. Because the filtering is at high molecular weight particles, the osmotic pressure differential across the surface of the membrane is minimal in this filtration process. As a result, high pressure is not essential to achieve high flux rates. The flux rate is the number of permeate products that flow through a membrane per unit area in a given time. It removes organic, inorganic polymeric molecules, colloidal material, and impurities of high molecular weight. But it is ineffective in removing low molecular weight ions or molecules such as Calcium, sulfate, Sodium and Magnesium Chloride.

- Working principle of Ultrafiltration Plant:

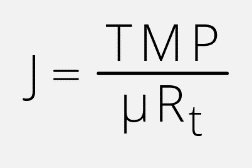

The general concept of Ultrafiltration is to separate solutes from a solvent by applying pressure to a semipermeable membrane. The Darcy equation describes the connection between the applied pressure on the solution to be separated and the flow through the membrane:

Where,

J = flux (flow rate/membrane area),

TMP = transmembrane pressure (pressure difference between feed and permeate stream),

μ = solvent viscosity,

Rt = total resistance (sum of membrane and fouling resistance).

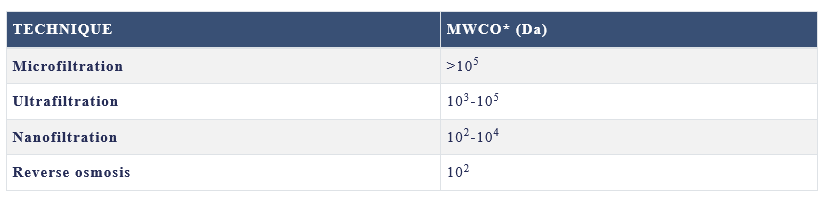

- Membrane Technology

- Application of Ultrafiltration Plant:

1. General – Ultrafiltration is used to recycle flow or add value to the following products in industrial sectors such as chemical and pharmaceutical manufacturing, food and beverage processing, and wastewater treatment.

2. Drinking Water – Ultrafiltration remove particles and macromolecules from raw water to make it drinkable. It is used to either supplant existing secondary (coagulation, flocculation, sedimentation) and tertiary (sand filtration and chlorination) filtering systems in the water treatment plant, or as standalone systems in isolated regions with growing populations.

3. Protein concentration – In the dairy industry, UF is commonly used to make whey protein concentrate (WPC) and lactose-rich permeate from cheese whey. In a single-phase, a UF Plant concentrate on whey 10–30 times the feed.

4. Other applications

- Filtration of paper pulp mill effluent

- Cheese manufacture, Ultra-filtered Milk.

- For removing bacteria’s from milk

- Wastewater treatment and process

- Enzyme recovery

- Concentration and clarification of fruit juice.

- Blood dialysis other blood treatments.

- Desalting and solvent-exchange of proteins (via dia-filtration)

- Manufacturing to laboratory standard

- Radiocarbon dating of bone collagen

- Ultrafiltration Plant removes:

- Endotoxins

- Colloids

- Pyrogens

- Bacteria

- Plastics

- Proteins

- Silica

- Silt

- Smog

- Viruses

Kelvin Water Technologies Pvt. Ltd. India, offers affordable, professional and user-friendly Ultrafiltration Plant & services in India. We are serving our clients from industrial, commercial & residential for more than 10 years and providing high-quality products and services. Our professional & innovative engineer specializes in offering custom & standard advanced process technology UF Plant to remove micro bacterial counts and is friendly, responsive and prompt. Our goal is to deliver comprehensive solutions for manufacturing, consultation, chemical & media supplies, AMC services, or any large or small turnkey project, in India.