-

Water, Waste Water and Organic Waste

Management Company -

email us

info@kelvinindia.in

-

call us now

+91 9812 24 1001

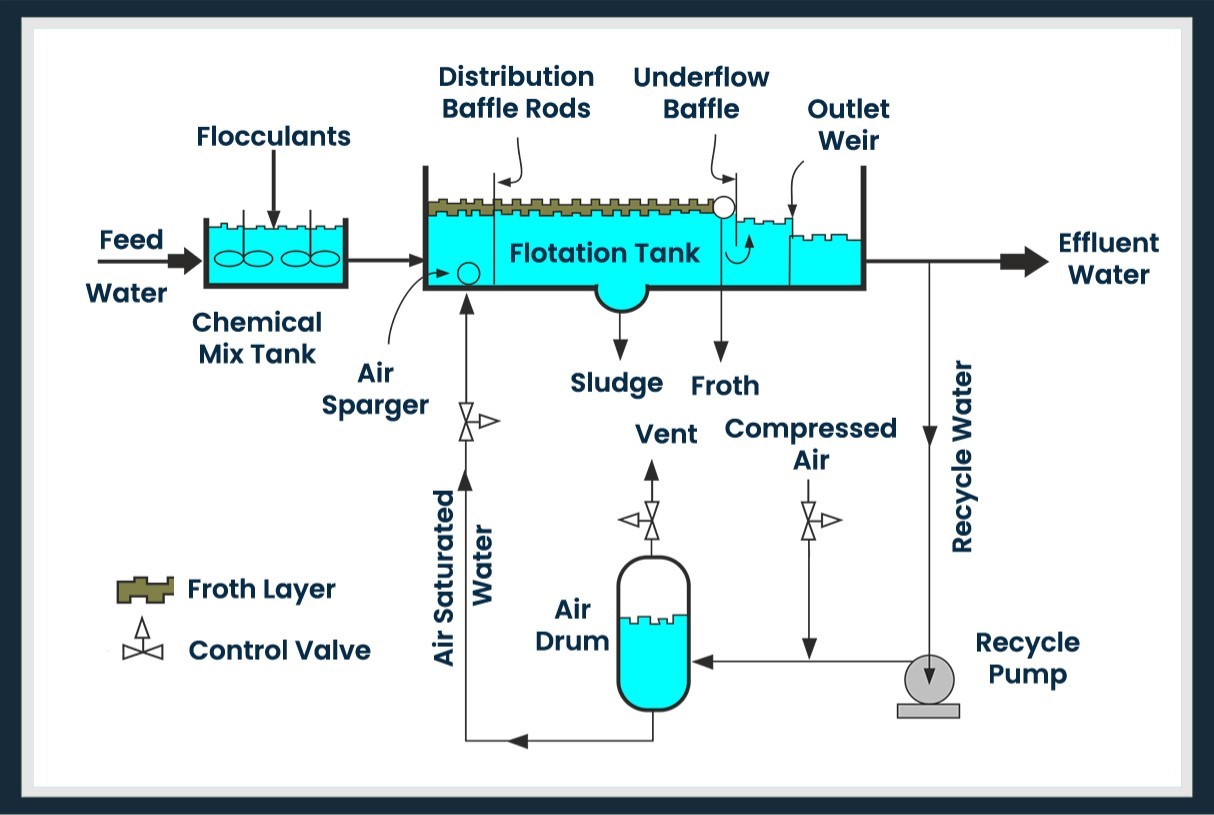

A Dissolved Air Flotation system (DAF) is a water management and treatment procedure. It clarifies effluent and waste waters by removing suspended matter in them like solids or oils. This clarification process is done by dissolving air in the waste water under pressure.

While the feed water enters the DAF float tank, coagulants are added. A part of the purified effluent water departing the DAF tank is thrust in the air drum, where the compressed air gets introduced. Consequently, the pressurized effluent water saturates with the air. This water flow gets recycled while going towards the tank's front. Then it runs through a pressure reduction valve as it goes to the tank's front. Thus, the air gets released as small bubbles. Bubbles get formed on the surface of suspended particles. The lift from bubbles defeats the gravity force. The suspended matter, in the form of froth, comes to the surface, which is later removed by skimming. Finally, the froth-free water leaves the float tank as clarified effluent.

Ans. DAF is a water treatment method that clarifies wastewaters by removing suspended particles such as oil or sediments. Air is removed from the water or wastewater by dissolving it under pressure in the water or wastewater and then releasing it at atmospheric pressure in a flotation tank basin. The expelled air forms tiny bubbles that cling to the suspended stuff, causing it to rise to the water's surface and be retrieved by a skimming equipment.

Ans. DAF systems are utilised in a variety of applications, such as:

Ans. DAF systems work by injecting fine air bubbles into the wastewater stream. These bubbles cling to the suspended particles, oil, and grease, forcing them to rise to the surface. The floating particles are subsequently skimmed off the water's surface, resulting in a clean and clear effluent. DAF systems are classified into two types: pressurised DAF and atmospheric DAF. Pressurized DAF systems are commonly employed in industrial applications with high pollutant concentrations, whereas atmospheric DAF systems are used for municipal wastewater treatment.

Ans. A DAF system consists of four major components: a flotation tank, an air compressor, a skimmer, and a chemical dosing system. The flotation tank is the DAF system's heart. That is where the wastewater is entered, and the flotation process takes place. Depending on the purpose, the tank is typically rectangular or circular in shape and size. The air compressor is used to create fine air bubbles that are then put into the wastewater. The compressor is typically positioned outside the flotation tank, and air is fed into the tank via a diffuser. The skimmer is used to remove floating particles from the water's surface. The particles are typically scraped into a trough by a spinning arm, where they are collected and flushed out of the system. The chemical dosing system is used to boost the flotation process by adding chemicals to the effluent. Coagulants and flocculants, for example, can help to clump the suspended solids together, making them easier to remove.

Ans. DAF systems outperform other wastewater treatment technologies in various ways. Among these benefits are the following:

High removal rates: DAF systems can remove 99% of suspended particles, oil, and grease from wastewater.

Reduced energy consumption: When compared to other treatment methods, DAF systems use extremely little energy, making them a cost-effective solution for many applications.

DAF systems have a small footprint and can be easily integrated into existing treatment plants, minimising the requirement for additional space.

Easy to operate: DAF systems are simple to use and require little maintenance, minimising the requirement for trained labour.

Versatile: DAF systems can treat a variety of wastewater streams, including industrial and municipal waste.

Ans. Due to the risk of explosion, dissolved gas flotation (DGF) units in the oil industry do not use air as the flotation medium. To make the bubbles, nitrogen gas is used instead.

Ans. The amount of air necessary for efficient flotation is approximately 6-10 g/m3 or 4-6 l/m3 of treated water, with a recycle flow rate of approximately 6-15% (usually 8-10%) depending on the temperature and dissolved oxygen concentration of the entering water.